- At home everywhere

OPTIMUM CLIMATE FOR ALL REQUIREMENTS

Meets all requirements

air distribution, comfort climate,

Hygiene or assembly / maintenance.

PRECISE WITH EVERY

APPLICATION CASE

- APPLICATION CASE

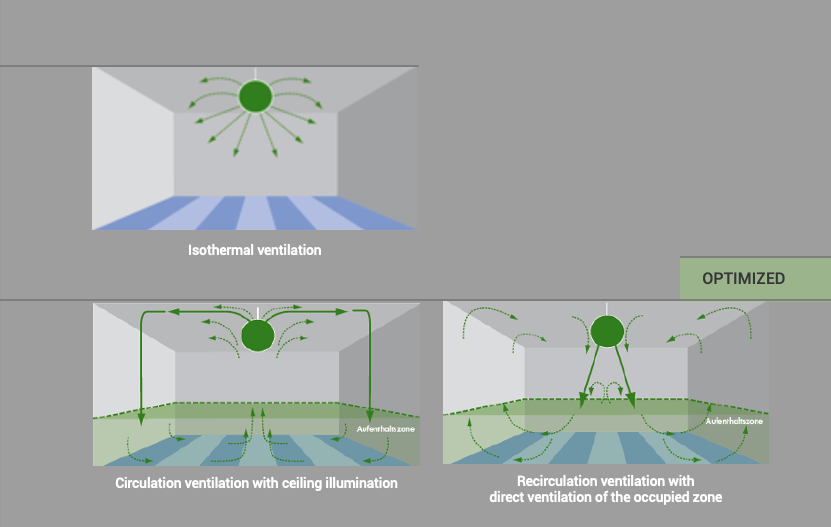

ISOTHERM

Air discharge: Fabric diffusion

Room ventilation through even air distribution

over the entire surface.

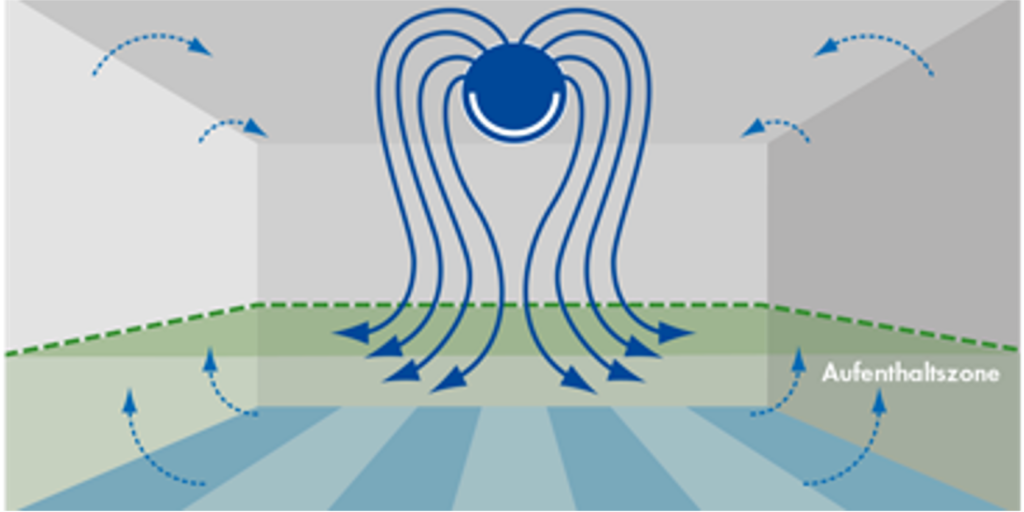

Room ventilation through targeted recirculation ventilation.

for air exchange at constant room temperature.

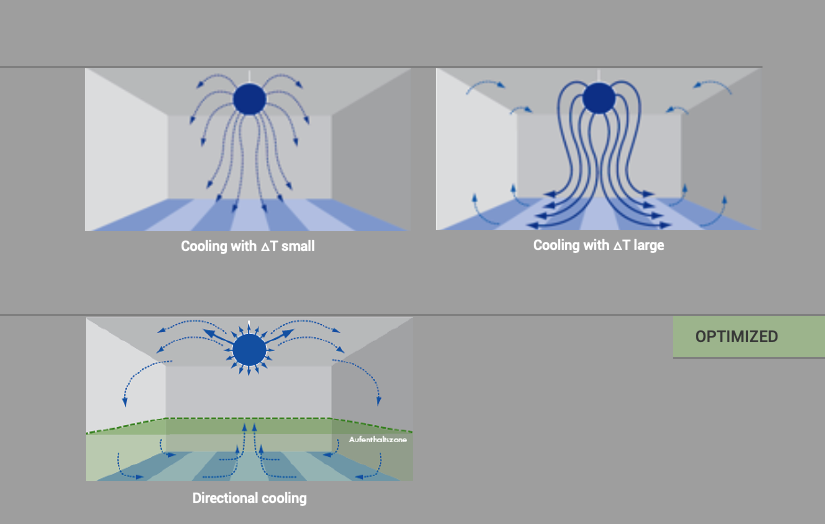

- APPLICATION CASE

COOLING

Air discharge: Fabric diffusion

Uniform draught-free room cooling through targeted air distribution for an optimized room climate.

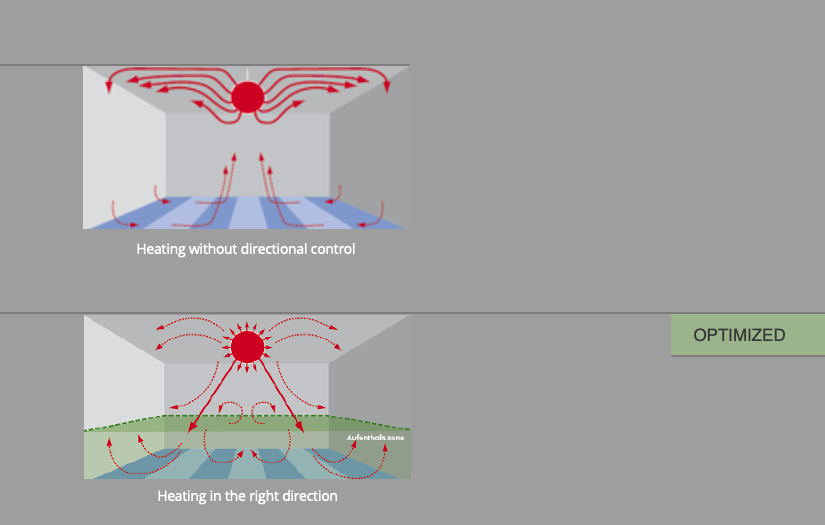

- APPLICATION CASE

HEATING

Air discharge: Fabric diffusion

Uniform air mixing through targeted air distribution for optimized heat distribution.

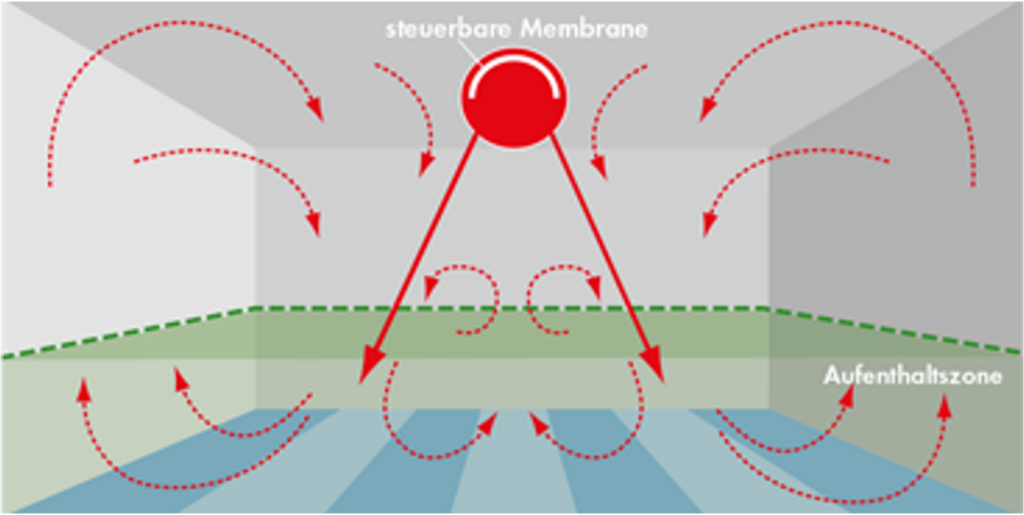

- THE COMBI TUBE

Heating and cooling in one

Depending on whether the system is operating in summer or winter, the actuator activates the corresponding heating or cooling mode.

The combination of fabric diffusion and directional perforation in one textile air distribution system enables both heating and cooling. This system cleverly utilizes the advantages of displacement ventilation and recirculation ventilation by switching between these two modes. The changeover between heating and cooling is controlled by an electromechanical actuator.

Depending on requirements, an integrated membrane within the tube allows either the upper or lower half of the hose to become impermeable to air. This means that in cooling mode, the cool air flows gently out of the upper half of the duct and slowly sinks to the floor without causing unpleasant draughts. When heating, on the other hand, the upper half of the duct is closed so that the warm air is directed downwards towards the floor for more efficient heat distribution and improved efficiency.

Actuator position: UP

Warm air is pressed downwards to achieve better mixing with the cooler air layer in the room.

Actuator position: DOWN

Cooled air is discharged upwards to achieve the widest possible distribution in the room.

Depending on whether the system is operating in summer or winter, the actuator activates the corresponding heating or cooling mode.

The advantages of displacement and recirculation ventilation are used alternately.

- When it comes to detail

State-of-the-art simulations

OUR SERVICE

In many applications, the specialist planners are supported by professional simulation software. We use ANSYS Fluent in the numerical flow simulation (CFD). This allows indoor air flows to be simulated realistically and significantly supports the product development of textile air ducts.

- DRAUGHT-FREE AIR DISTRIBUTION

THE RIGHT COMBINATION

COMPARISON BETWEEN

FABRIC DIFFUSION AND FABRIC DIFFUSION WITH ADDITIONAL PERFORATION

Homogeneous air velocities can be generated in the room with the perforation air duct type. The forced air rollers mix the room air and therefore provide a more comfortable climate in the occupied zone.

In the simulations below, a specific customer project was visualized with a temperature difference of -6K at a supply air temperature of 18°C and a cooling load of 325W per meter of air outlet.

The result of this optimization is a further significant reduction in air velocity and almost homogeneous air distribution throughout the room.

OPTIMAL CLIMATE WITH

ALL REQUIREMENTS

Ideal for all requirements for

- AIR DISTRIBUTION

- COMFORT CLIMATE

- HYGIENE

- ASSEMBLY

- MAINTENANCE